Biomass Heat Recovery

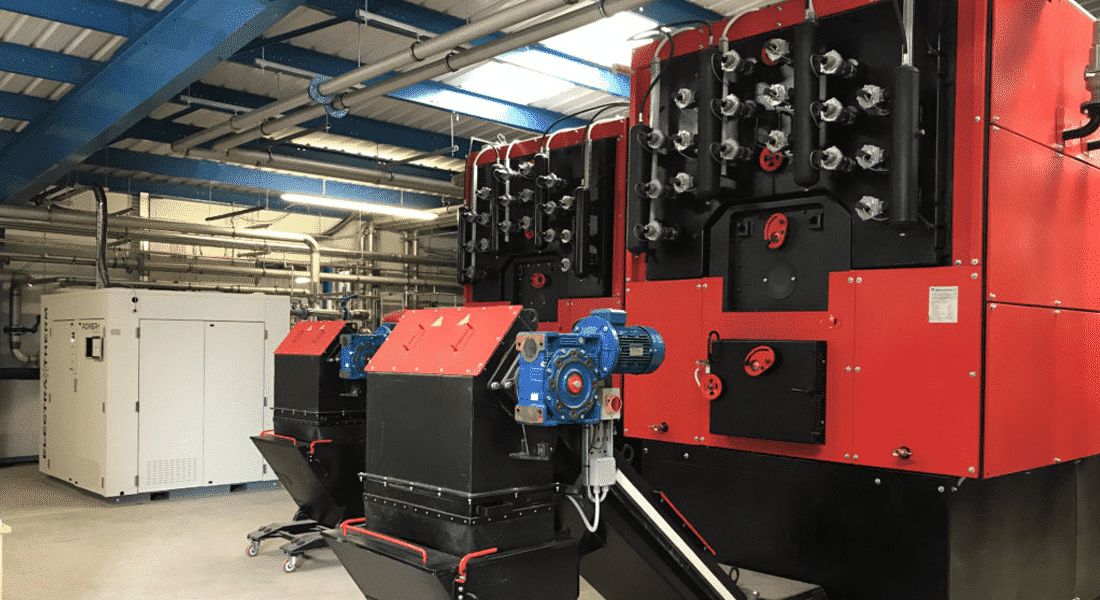

Biomass is one of Earth’s most abundant organic sources of energy. Boilers have been used for over a century to dispose of vegetable waste and wood by-products while providing usable thermal for heating and power applications. Boilers are also extensively used alongside anaerobic digestors in the production of biogas – providing heating solutions to the site. However during these processes a substantial amount of energy is lost as waste heat.

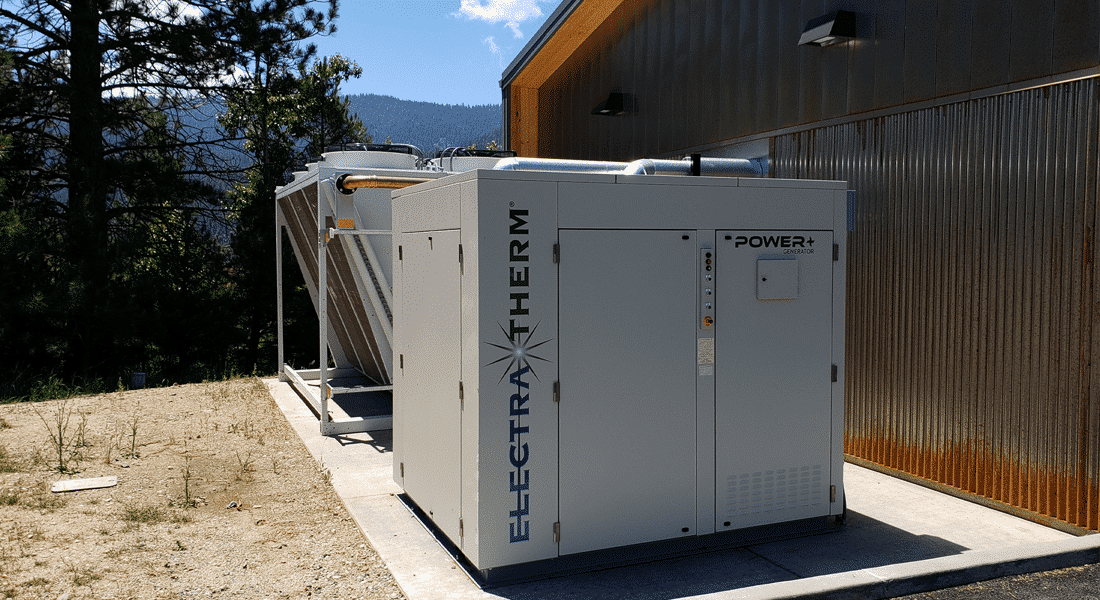

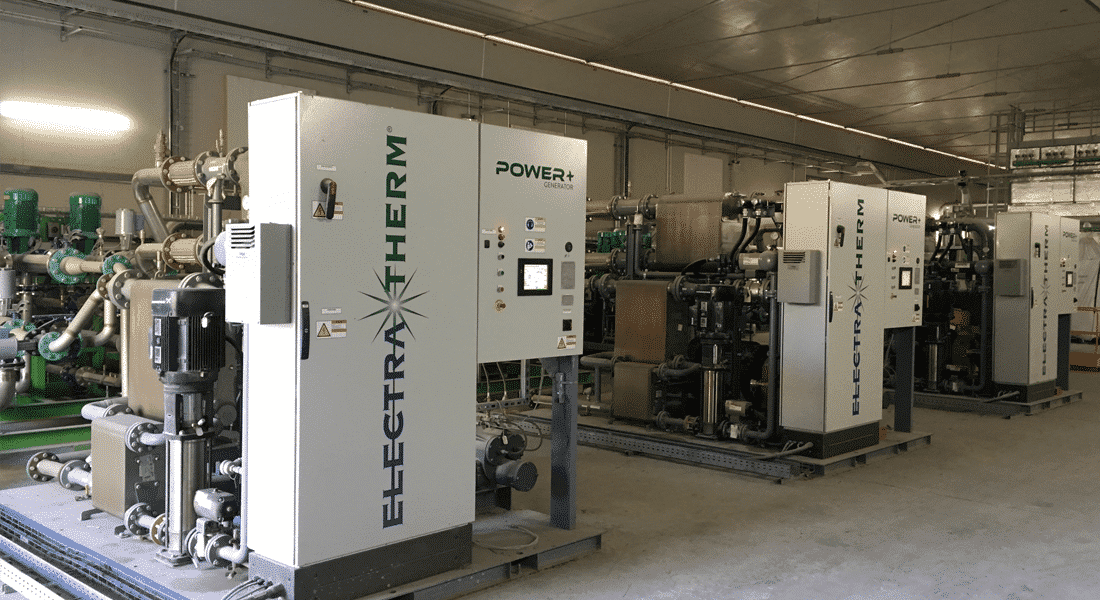

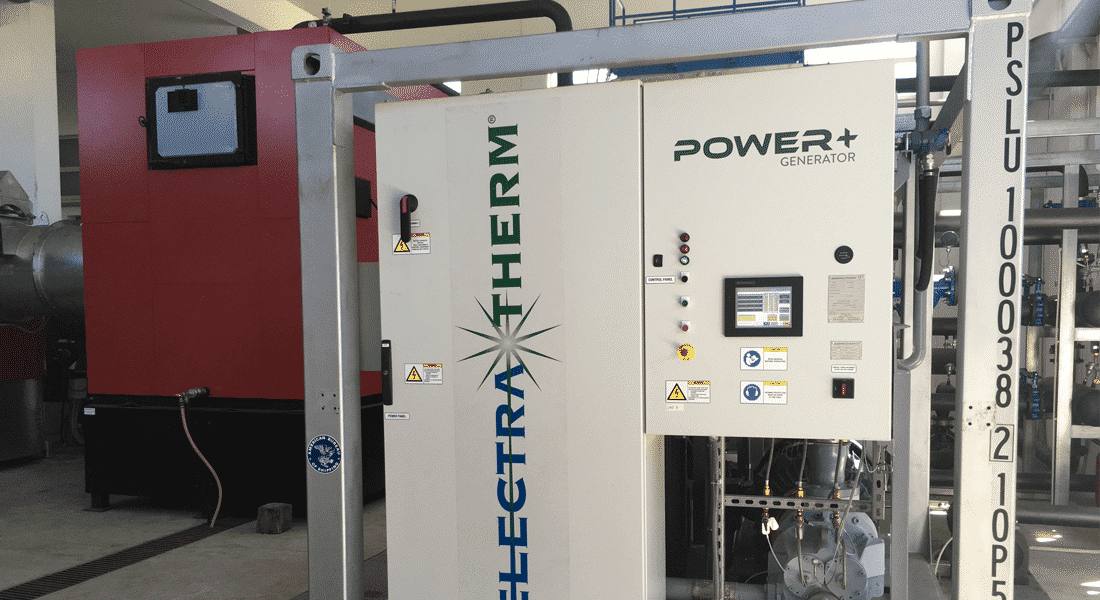

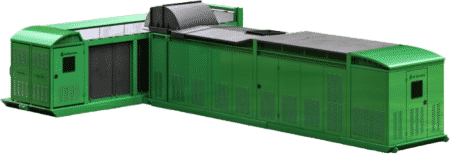

By utilizing ElectraTherm’s Organic Rankine Cycle (ORC) heat to power system, the heat produced from these boilers can be further utilized to generate emission-free power and provide district heating as a CHP unit. ElectraTherm has been demonstrated with the U.S. Department of Defense and is currently in a cooperative agreement with the U.S. Department of Energy for ORC combined heat and power.

Questions?

Contact us and we will be happy to help.