Active Cooler

Net-Zero Cooling to Power Technology

Power generation and industrial processes generate considerable heat loads, requiring cooling systems to reject the heat. This is not only a waste of energy but consumes additional power leading to increased costs and emissions.

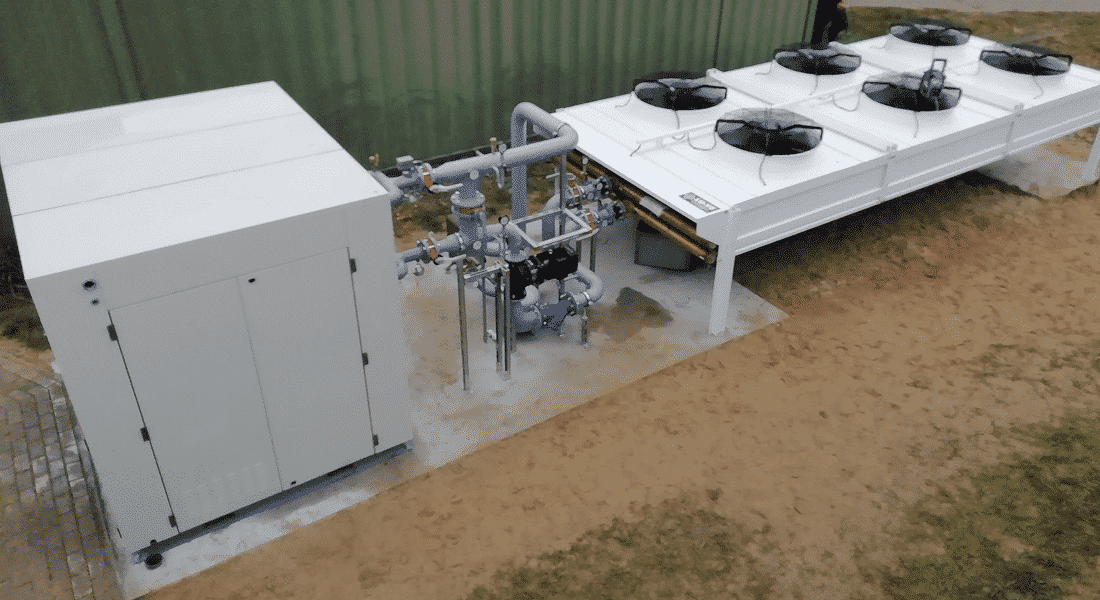

The Active Cooler converts the heat from engine cooling circuits into clean electricity while eliminating parasitic cooling loads. This leads the system to act as a net-zero cooling solution with the added benefit of power generation when conditions are optimal.

During peak cooling demand, the ORC expander is bypassed and the system prioritizes cooling, fulfilling cooling requirements regardless of power generation. This is the only time, other than initial startup, that the Active Cooler will consume power that is not its own.

| MODEL | AC800 |

|---|---|

| Heat Rejected* | > 380 kWth |

| Hot Water Temp** | 158 - 240°F // 70 - 116°C |

| Hot Water Flow | 45 - 240 gpm // 3 - 15 l/s |

| Cold Water Temp | 40 - 150°F // 4 – 65°C |

| Cold Water Flow | 95 - 285 gpm // 6 - 18 l/s |

| Max (Gross) Output | 75 kWe |

// Weight: 4,800 kg (skid option)

// Dimensions: 2.4m x 9.5m x 1.75m (W*L*H)

*Loads larger than 800 kWth may require a custom design or secondary unit.

** Higher temperature heat sources require an additional heat exchanger.

// Provides full-load cooling for the engine.

// Generates up to 75 kWe (gross).

// Zero emissions or fossil fuel requirements.

// Increases efficiency by offsetting the cooling load.

// Modular, scalable system that can be adjusted to fit changing needs.

// Closed-loop system minimizes water consumption.

// Induction generator allows for simple electrical connection and start up.

// Reduces engine derate due to insufficient cooling.

// A simple and reliable baseload power supply in remote areas.

// Serves as a radiator / cooling tower alternative, offsetting capital costs.

// Easy installation with remote operation.

// Simple, robust design with minimal footprint.

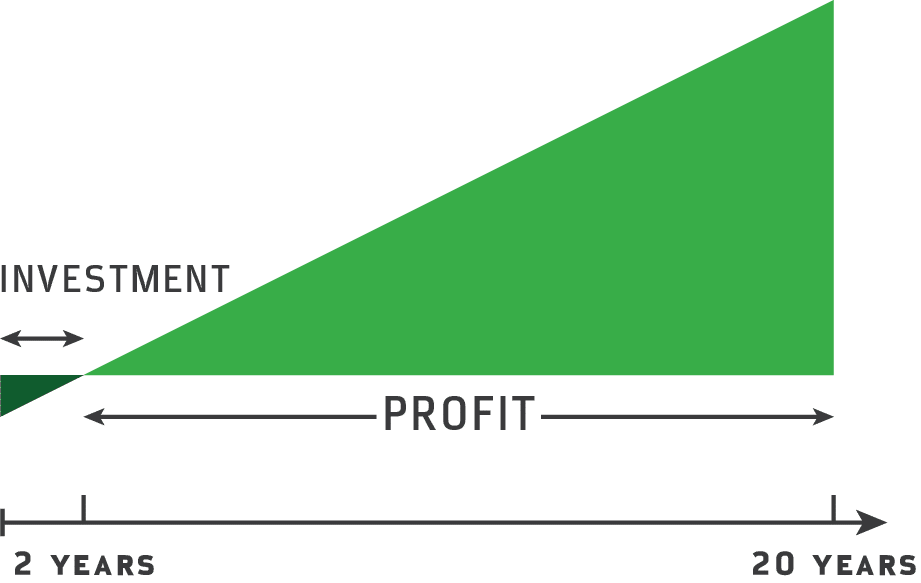

// Short payback period (2 – 5 years).

// Qualifies for clean energy incentives.*

* Incentive eligibility varies based on region.

Typical Applications

The Active Cooler is an ideal fit for any business that implements commercial cooling to expel heat greater than 70°C (greater than 400 kWth). Common industries that could benefit from net-zero cooling to power include manufacturing, air / gas compression, wastewater treatment, biogas production as well as sectors that generate power such as power plants, landfills, well pads, and other micro-grids. These industries produce large amounts of heat and require cooling. Designed with flexibility in mind, the Active Cooler is easily integrated into existing systems and scalable to multiple megawatt heat loads.

Numerous Benefits

Not only is engine cooling an unavoidable operating expense, but all radiators must be replaced eventually. By installing an Active Cooler as a radiator alternative, you benefit from the offset cooling load in addition to increased efficiency through either reduced fuel consumption or increased power output – with no additional fuel consumption or emissions.

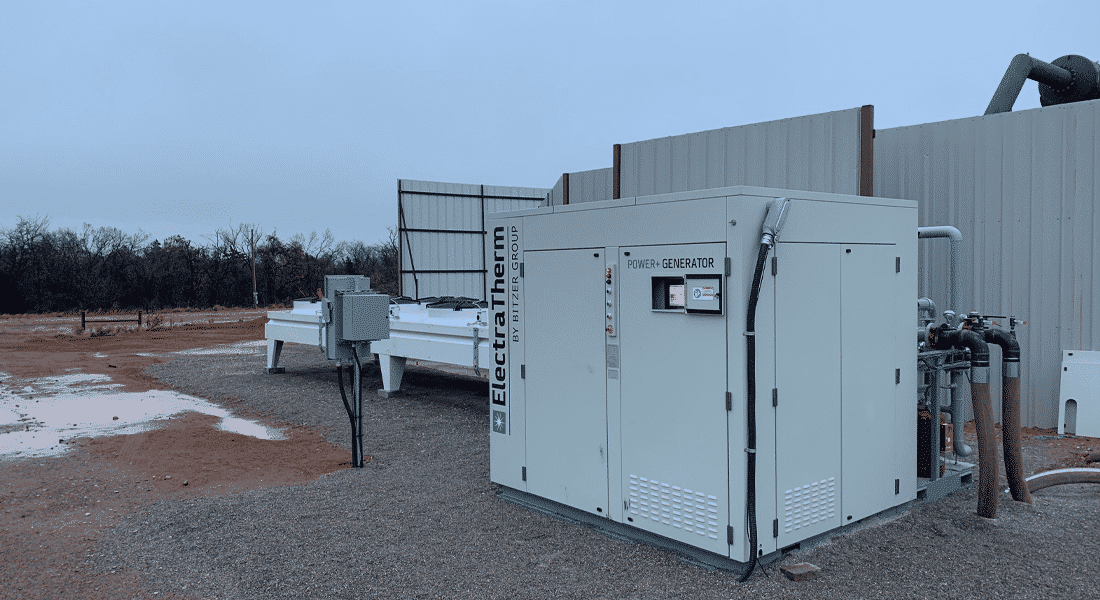

For remote applications, such as oil and gas operations, the ability to serve as a net-zero cooling system as well as a micro-grid providing a baseload power supply allows operators to implement processes that rely on electricity, a commodity previously not provided.

FAQS

Yes, but our system requires 480V power and large power plants may only have higher voltage, therefore needing a 480V transformer. However, most utility scale power plants should have 480V power available for other site loads.

Based on internal case studies, a single Active cooler is a good fit for (2-3) 2000 bhp engines or (1) 5000 bhp engine.

The Active Cooler significantly reduces the cooling load of the radiator / cooling tower. Capable of serving as a highly efficient alternative to the existing cooling system, the Active Cooler effectively replaces the radiator / cooling tower.

The Active Cooler serves as an alternative for either, our system currently uses an internal fin fan.

As long as the temperature of the heat stream currently being cooled by the tower is high enough for us to utilize (Greater than 70°C / 400 kWth).

If the heat is there then it is certainly economical to replace any standard cooler with the Active Cooler. Standard coolers reject heat at the cost of parasitic load from the water pump, fan power, etc. Alternatively, the Active Cooler uses that heat to generate power that not only offsets the parasitic load but provides additional power to the site – increasing energy efficiency.

Not only are capital costs offset since a cooling system is required but ORC technology in the U.S. can be eligible for a 26% federal tax investment credit. Projects typically see a return on investment between 2 and 4 years.

The condensing circuit of the Active Cooler is closed-loop so there should be no loss of water in our process. Plants using “wet” cooling towers will see a significant reduction in freshwater consumption.

Not necessarily. The cooling to power system will need the same amount if not slightly more space. However, if replacing part of the load in a power plant then overall surface area required to manage the cooling load is reduced.

The Active Cooler converts 5-10% of the heat into electricity, reducing the cooling load 70-100%. Even so, when the cooling demand is high, excess heat will bypass the ORC and will be dissipated through the Active Cooler’s integrated radiator. The system size varies on the amount of thermal needed to be rejected at peak demand.

Many PTO-fan compression engines face noise-related challenges, driving operators to utilize electric fan table-type coolers. Collected data suggests PTO fan sound levels average around 90 dB(A) at ten meters, our integrated cooler is rated at 63 dB(A) at ten meters.

EXAMPLE APPLICATION

1.6 MW CAT 3530C

// Average Annual Temperature: 65°F

// 8,500 operating hours per year

// Hot Water Inlet: 230°F @ 220 gpm

// Radiator Demand: 10 kW

//Parasitic Cooling Load: 85 MWh/yr

// Parasitic Cooling Cost: -$8,500/yr at $0.10/kWh

// AC800 Production: 570 MWh/yr

// Newly Available Electricity: 655 MWh/yr

// Total Savings: $65,500/yr at $0.10/kWh

// Total Savings: $98,250/yr at $0.15/kWh

// Efficiency Increase: 4.8%

Good For The Environment

WHAT ONLY 5 ACTIVE COOLERS COULD DO FOR YOU…

By upcycling waste heat into usable power you generate 3,285 MW of clean electricity and offset the equivalent of 2,330 metric tons of carbon dioxide annually.

Your annual pollution offset is equal to taking 500 cars off the road, or reducing gasoline consumption by 260,000 gallons.

Your pollution offset is equivalent to the carbon sequestered by a 2,850 acre forest, or 100,000 mature trees.

The clean power generated is equivalent to the emission offset of 420 homes’ electricity use annually, or 95,000 cylinders of propane used for backyard barbeques.

Source: EPA Greenhouse Gas Equivalencies

*Calculations based on (5) Active Coolers generating 65 kW net and offsetting 10 kW each.

Good for business

Simple. Reliable. Profitable. Sustainable.

Simple

The simple and flexible nature of our ORC solutions allows them to be adjusted to fit the needs of any application. A robust, modular, and scalable design allows the system to be easily integrated into existing processes while allowing for future adjustments. Able to successfully operate at partial loads with varying conditions also means that they will produce electricity even when your processes are not at capacity.

Reliable

Every ElectraTherm product goes through a rigorous testing process at our world-class R&D test cell to ensure absolute reliability. With a global fleet of over 100 units clocking over 2,000,000 operating hours with 24/7 access to our team as well as dedicated partners, you can have peace of mind knowing that we confidently stand behind our products.

Profitable

Our systems use existing heat as fuel, keeping operating costs minimal. ElectraTherm converts this heat into clean electricity, ready immediately. The Active Cooler is a net-zero cooling to power solution that provides cooling as well as power – making the Active Cooler the perfect radiator alternative. This increases energy efficiency – up to 10% – while substantially reducing energy consumption. ElectraTherm’s ORC solutions may also qualify for local sustainability incentives as well as enabling micro-grid functionality in remote regions. With an impressive 20-year design life and a payback period of 2-3 years, the economics amount to an attractive return on investment.

Sustainable

Over 50% of energy used in power generation and industrial processes is lost as heat – making this heat an enormous source of renewable energy. Increasing energy efficiency by upcycling this waste heat into emission-free electricity is the single easiest way to mitigate emissions and achieve sustainability goals. Cooling to power means no more compromising efficiency or power output for cooling. Cooling to power means replacing a power-hungry radiator with a power-producing Active Cooler. Cooling to power means improving your bottom line and the environment.

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.