Converting Heat Into Clean Electricity

The Future of Energy Efficiency

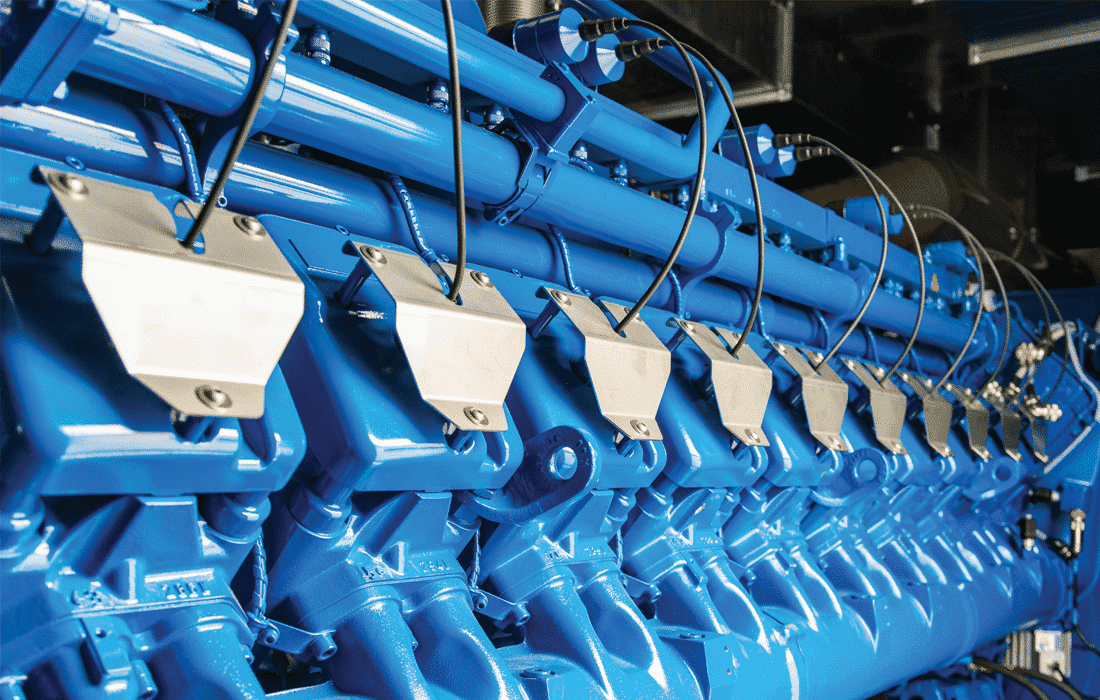

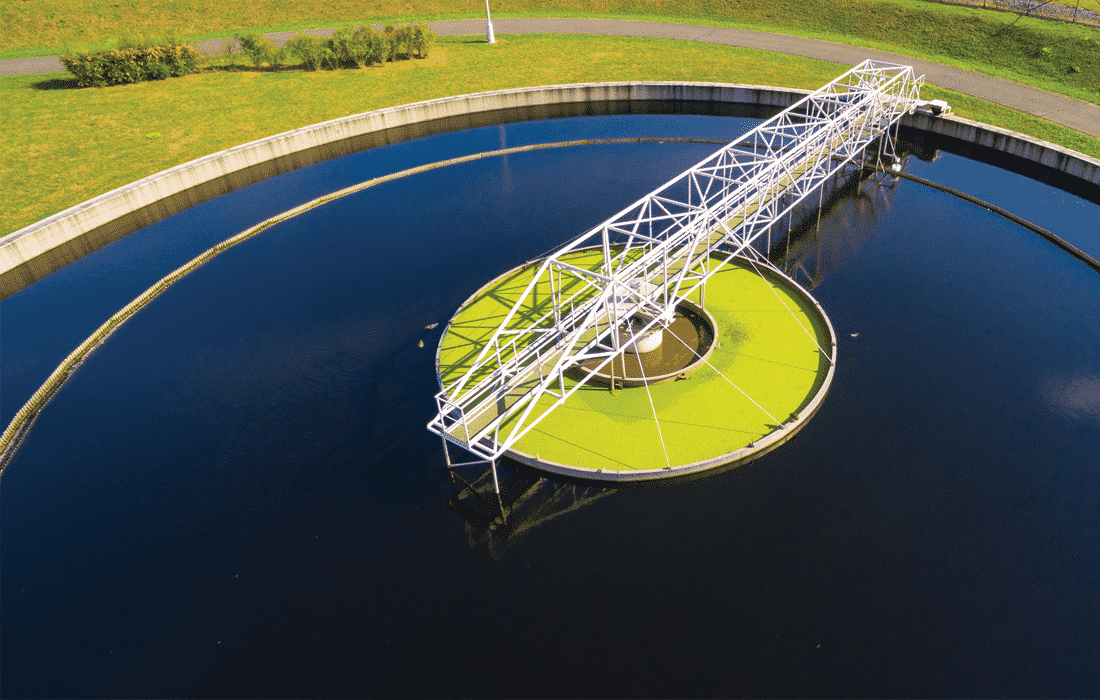

We use an Organic Rankine Cycle (ORC) along with proprietary technologies to convert waste heat and geothermal heat into clean electricity – with no additional fuel consumption or emissions. Our low temperature waste heat recovery solutions use hot water as a thermal medium to power a closed-loop system, providing up to 150 kWe in addition to reducing the parasitic load.

Reduce Costs

Our solutions increase efficiency by converting unused heat into clean electricity while simultaneously reducing or eliminating the cooling load, further offsetting energy demand.

Operators benefit from lower energy costs and are typically eligible for incentives promoting energy efficiency, cogeneration, geothermal generation, and other clean energy initiatives.

Reduce Emissions

Many power generation and industrial processes see approximately 60% of fuel energy lost as waste heat. By capturing this heat you prevent the waste of energy, generate clean electricity, and mitigate emissions. A win-win-win.

Our solutions are proven to decrease fossil fuel consumption and their related emissions, reduce or eliminate flaring, as well as reducing reliance on the grid by providing a dependable electrical supply.

Increase Efficiency

Capable of generating up to 150 kilowatts of clean electricity from waste heat, our systems increase efficiency up to 10% – either by reducing fuel consumption and emissions or by increasing power output.

Our newly available net-zero cooling solution is capable of offsetting cooling loads while generating electricity. Low temperature waste heat recovery is the future of energy efficiency.

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.

Announcements

Factors that make a successful application

HEAT

Our systems utilize heat sources above 70°C to convert thermal energy into clean electricity. Higher temperatures correlate to higher power output thereby achieving a quick return on investment. Other variables that play a role in determining power output are the ambient temperature, flow rate, and hot/cold water temperature differential.

RUN HOURS

Some units run all the time, and some are only used intermittently. There are 8760 hours in a year, the more of these an application is operational the faster the return on investment.

VALUE OF POWER

The electricity generated by ElectraTherm’s ORC systems can be sold to the grid or used to offset power demand – serving as a revenue stream for many years to come. The higher the value of power, the faster the return on investment.

UTILITY

Companies looking to leverage sustainable technology that actively supports ESG initiatives can do so with the help of our ORC systems. From recycling wasted thermal energy and reducing emissions to serving as a micro-grid component providing electricity at remote sites, ElectraTherm’s solutions provide a range of benefits.

Applicable fluid heat sources are between 70°C – 150°C (158°F – 302°F).

Heat sources above 150°C (302°F) — such as exhaust gases and thermal oils — can be utilized with the deployment of an additional heat exchanger.