Power Generation

Engine Waste Heat Recovery

Combustion engines see extensive use across the globe for their reliable power generation capabilities. From diesel prime power for remote power generation, gas compression, and providing power for industrial processes – combustion engines have the ability to generate anywhere from just a couple kilowatts to several megawatts of electricity. However, even with huge leaps in technology, gensets typically lose over 50% of the their input energy to waste heat.

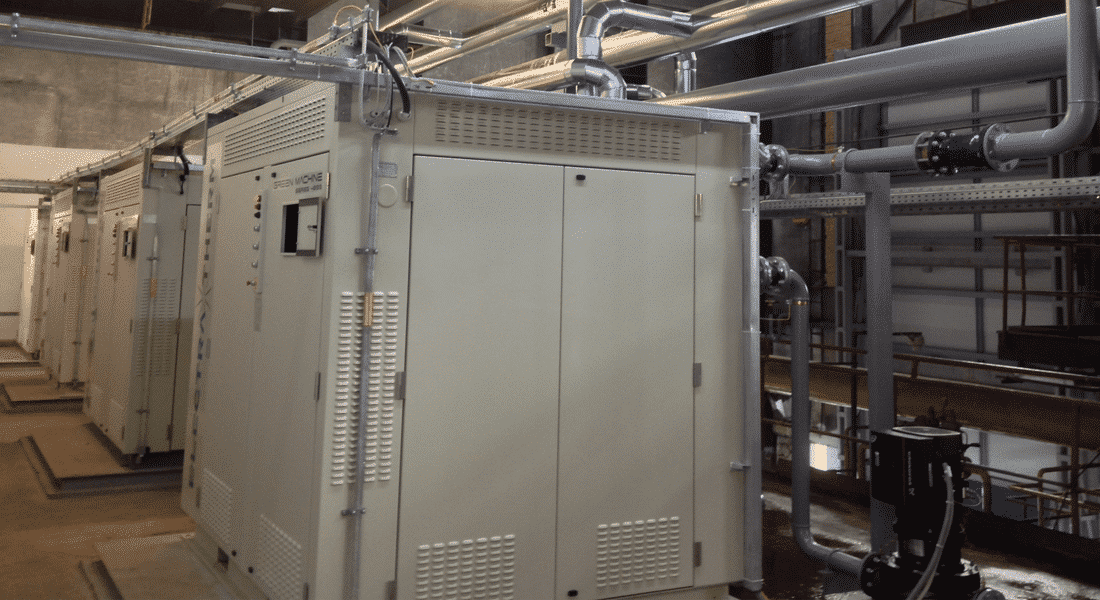

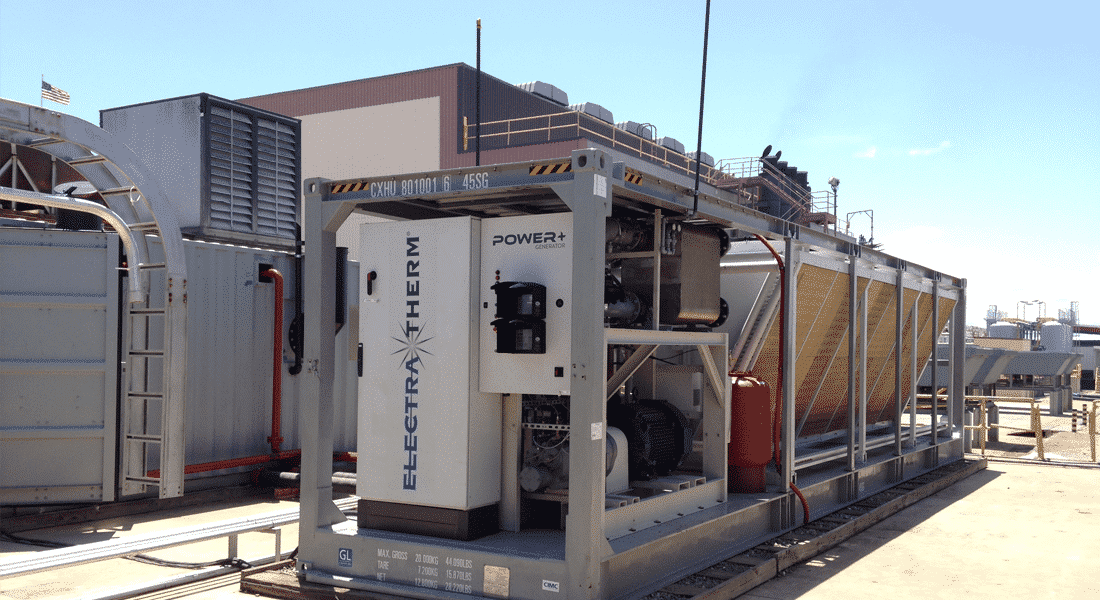

ElectraTherm’s Organic Rankine Cycle (ORC) solutions, the Power+ Generator and Active Cooler, are able to capture and utilize this engine waste heat to increase efficiency up to 10%, which leads to significant energy savings. There are several other benefits such as reducing engine derate, remote generation of electricity, and even achieving net-zero cooling in addition to power generation.

Factors That Make A Successful Application

HEAT

The amount of heat available is the largest factor in determining if a heat source is viable for ORC heat recovery. While heat sources as low as 70°C can be used, heat sources above 100°C are considered ideal. Other variables that play a role in determining output are the ambient temperature, flow rate, and hot/cold water temperature differential.

RUN HOURS

The more time an application is operational, the more heat there is available to convert into electricity. There are 8760 hours in a year and suitable applications will experience 80% up-time.

COST OF POWER

Installing an ElectraTherm ORC comes with several benefits, one of those is increasing efficiency and reducing energy dependence on the grid. Projects located in areas with high costs of power see the fastest returns on investment.

UTILITY

Companies looking to leverage sustainable technology that actively supports ESG initiatives can do so with the help of our ORC systems. From recycling wasted thermal energy and reducing emissions to serving as a micro-grid component providing electricity to remote regions, ElectraTherm’s solutions provide a range of benefits.

Increase Efficiency

Decrease Costs

The graphic to the side represents the typical energy split in a combustion engine. As you can tell, a majority of the applied energy is lost as waste heat. ElectraTherm’s solutions convert engine waste heat – either from the jacket water or exhaust gas – into usable power. This process reduces the radiator cooling load and generates electricity that can be used to provide additional horsepower, improve the engine’s fuel economy, or sold for profit. By taking advantage of waste heat – and with no additional fuel consumption or emissions – efficiency is increased up to 10%.

Combined Heat and Power

ElectraTherm’s Power+ Generator can double as a CHP unit that improves efficiency and your bottom line. ElectraTherm’s ORC systems are capable of generating up to 150 kW of clean electricity while providing up to 85°C of usable thermal.

The 6500B and 6500B+, optimal for CHP applications, are capable of transferring 2+ megawatts of heat. This reduces the cooling load, energy costs and possibly even allows the system to serve as a radiator alternative. ElectraTherm has an extensive amount of machines installed on CHP applications, contact us for references or to arrange a site visit.

Net-Zero Cooling To Power —

Replace Your Radiator

Engines and industrial processes generate large amounts of heat and require cooling. This waste heat and cooling load places a burden on the engine, stealing away valuable power. With the ElectraTherm Active Cooler you can cool your engine while generating electricity.

ElectraTherm’s ORC solutions reduce the jacket water loop cooling load 70-100%, significantly decreasing the intercooler radiator temperature. This cooling effect allows the ElectraTherm unit to prioritize the production of electricity. If the cooling load is too significant, the ORC is bypassed and the system will provide full-load cooling, independent of the generator’s status.

By utilizing your waste heat and reducing dependence from the grid, direct and indirect emissions are reduced. A fully utilized Power+ Generator on a diesel genset has the ability to reduce emissions by over 600 metric tons annually.

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.