Power Module75

Next Generation Heat Recovery Solution

Using an organic Rankine cycle (ORC) along with proprietary technologies, the POWER MODULE75 converts sources of geothermal heat and waste heat into electricity – with no additional emissions or fuel consumption.

ElectraTherm’s heat recovery systems, which are ideal for small- and mid-scale applications, utilize low temperature heat sources previously deemed insufficient for power generation to do just that – generate power. The POWER MODULE75 effectively utilizes available thermal energy (excess heat) to produce clean electricity. Higher temperature heat sources – such as thermal oils and exhaust gases – can be utilized with the deployment of an additional heat exchanger.

| MODEL | POWER MODULE75 |

|---|---|

| Max Output | 75 kWe |

| Thermal Input | 300 - 1250 kWth |

| Hot Water Temp | 150 - 270°F // 65 - 132°C |

| Hot Water Flow | 47- 365 gpm // 3 - 23 l/s |

| Cold Water Temp | 50 - 150°F // 10 - 65°C |

| Cold Water Flow | 95 - 412 gpm // 6 - 26 l/s |

| Heat Rejected | 300 - 1200 kWth |

// Weight: 5700lbs. (2591 kg)

// Dimensions: 72″ (1.8m) x 95″ (2.4m) x 85″ (2.2m) (W*L*H)

Our heat recovery solutions are available as either standalone units or fully-packaged systems – depending on the existing infrastructure. Need help determining which ORC system is right for you? Fill out our Project Evaluation Form or Contact Us.

// Generates up to 75 kWe (gross).

// Increases efficiency, reduces fuel consumption and emissions up to 10%.

// Zero emissions or fossil fuel requirements.

// Modular, scalable system that can be adjusted to fit changing needs.

// Simple, robust design with minimal footprint.

// Closed-loop system minimizes water consumption.

// Easy installation with remote operation and monitoring.

// Short payback period (2 – 5 years).

// NEMA 3R / IP 54 compliant, CE certified.

// Sound attenuated option <72db at 1 meter.

// Qualifies for clean energy incentives*

* Incentive eligibility based on region.

THE SMART POWER DIFFERENCE

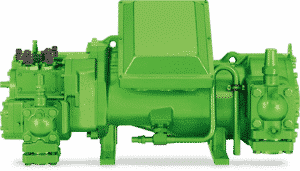

The integration of a semi-hermetic, twin-screw expander gives ElectraTherm’s ORC systems an advantage over competitive technologies and opens market opportunities where waste heat recovery has previously been either impossible or unpractical.

The custom built expander, along with proprietary technologies and lower operating speeds, provides a more cost-efficient, robust design that greatly enhances reliability and functionality. ElectraTherm’s ORC process utilizes much more variable heat sources made possible by the expanders’ ability to handle “wet” dual-phase flow, leading to greater turndown ratios which allow for continuous power generation when dealing with inconsistent thermal conditions.

For more information on our system’s capabilities, click here.

Good For Business

Simple. Reliable. Profitable. Sustainable.

Simple

The simple and flexible nature of our ORC solutions allows them to be adjusted to fit the needs of any application. A robust, modular, and scalable design allows the system to be easily integrated into existing processes while allowing for future adjustments. Able to successfully operate at partial loads with varying conditions also means that the system will produce electricity even when your processes are not at capacity.

Reliable

Every ElectraTherm product goes through a rigorous testing process at our world-class R&D test cell to ensure absolute reliability. Our technicians and dedicated global partners offer full support for any issues you may encounter throughout the product lifecycle.

Profitable

Our systems use existing heat as fuel, keeping operating costs minimal. ElectraTherm converts this heat into clean electricity, ready immediately. This increases energy efficiency – up to 10% – while substantially reducing energy consumption, primarily the cooling load. ElectraTherm’s ORC solutions may also qualify for local sustainability incentives as well as enabling micro-grid functionality in remote regions. With an impressive 20-year design life and a payback period of 3-5 years, the economics amount to an attractive return on investment.

Sustainable

Over 50% of energy used in power generation and industrial processes is lost as heat – making this heat an enormous source of renewable energy. Increasing energy efficiency by upcycling this waste heat into emission-free electricity is the single easiest way to mitigate emissions and achieve sustainability goals.

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.