Oil and Gas Operations

Oil and Gas ORC Heat Recovery

Oil and gas operations have valuable assets that are routinely wasted in the normal course of production.

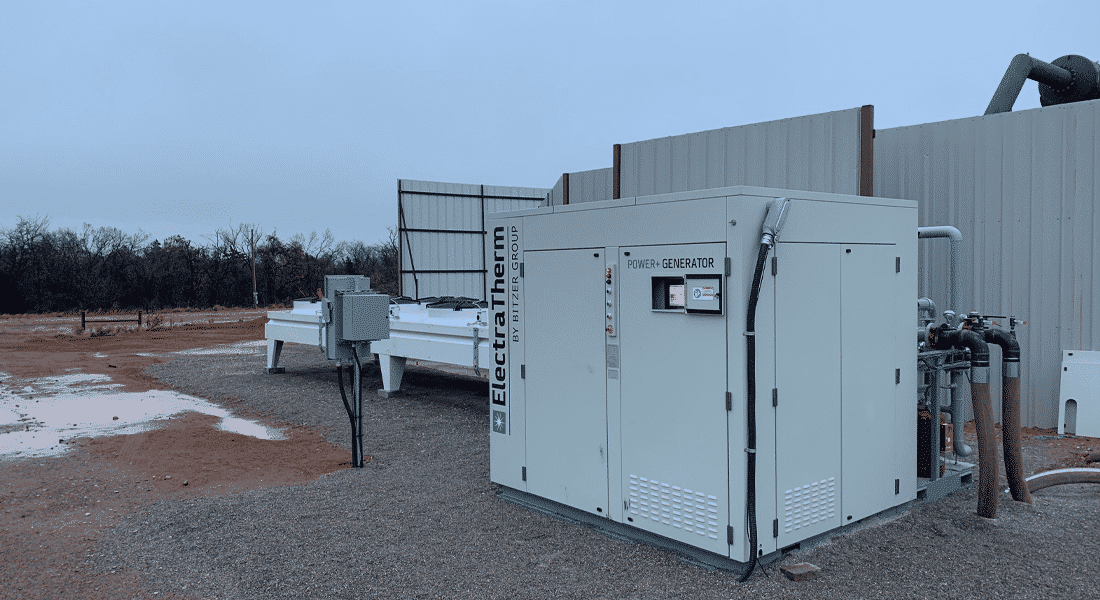

The oil and gas industry stands to benefit greatly from integrating ElectraTherm’s fully-packaged Organic Rankine Cycle (ORC) systems to convert waste heat into emission-free electricity. With the industry coming under increasing scrutiny, staying ahead of the curve and applying modern technologies to improve business processes is essential.

Oil and gas ORC applications could be the differentiating factor for many operators seeking to…

- achieve net-zero cooling, generate clean power

- increase efficiency, maximize revenue

- exceed air quality standards, reduce or eliminate gas flaring

- add geothermal co-production to active sites

- repurpose existing infrastructure for ORC geothermal power generation

Achieve net-zero cooling, generate clean power from oil and gas operations

In the oil and gas industry, there is a significant amount of energy lost to waste heat that can be capitalized on. ElectraTherm helps with waste heat recovery and converts that energy into clean electricity. Sources of the waste heat available for recovery and conversion include:

- exhaust of hot combustion gases

- cooling water

- radiative losses from hot equipment

High or medium temperature fluids can be run through the ElectraTherm in a heat capture / heat exchange process. The temperature of the waste heat is used for energy and the fluid is cooled, while generating clean energy. At the end of the cycle, the fluid used has a lower temperature, and the operation has gained clean power.

Depending on the volume and temperature of the fluid that needs to be cooled, the payback period generally ranges from two to five years. After that, it is free, clean energy and net-zero cooling.

Increase efficiency, maximize revenue

When you capture the waste heat and generate electricity, you automatically increase the efficiency of your oil and gas operation by harnessing the heat energy that is normally discarded. There is untapped value in the energy in waste heat, or the gases that contain such energy. With ElectraTherm’s combination of ORC and proprietary technologies, you will be able to access energy that otherwise would have been lost to the atmosphere to increase efficiency and revenue.

Capturing industrial waste heat increases the efficiency of your operation by utilizing a resource that you already own and haven’t harnessed. The increase in efficiency comes from reducing the loss of valuable energy. Once it is captured and converted, it can be used to decrease operating costs and increase revenue.

With our Power Module75 or Power+ Generator, electricity can be generated on-site and added directly back into your operation, or sold back to the grid. With a payback period of 2 to 5 years for most applications, this represents an opportunity for additional, ongoing revenue with virtually zero impact on your operation.

Being able to produce your own electricity on site has additional benefits for resiliency. If the power grid around you goes down, creating your own electricity from a generator can be expensive. Using the ElectraTherm equipment, electricity is generated at no additional cost (after the initial investment), therefore avoiding downtime and increasing the efficiency of your operation.

Repurpose oil and gas infrastructure for ORC geothermal power generation

Repurposing existing infrastructure is one of the most efficient business moves an operator can make. By definition, infrastructure represents a significant investment, often taking a decade or more to return an investment. When you add in the cost of retiring such an investment, the costs become astronomical, and weigh heavily on profits.

As stated in Oil and Gas Journal: “Repurposing existing oil and gas wells for geothermal applications eliminates drilling costs for new geothermal wells and eliminates plug and abandonment (P&A) costs for decommissioned wells.”

Repurposing existing oil and gas wells to harness heat instead of fossil fuels turns out to be a huge win for everyone involved.

- Reuse the existing wells on existing lands

- No need to do more exploration since the asset already exists

- Infrastructure around the well (roads, buildings, utilities) don’t need to be added to a new site, or decommissioned

- Energy extracted from the earth is free energy

- Geothermal is clean energy — a consumable commodity that is in increasing demand

Exceed air quality standards, reduce or eliminate gas flaring

According to Environment Journal, gas flaring contributes around 2% of the total greenhouse gas emissions in the world. As the world focuses more on reducing GHGs, this makes gas flaring a highly visible target for inspection. By using flare gas to produce energy, this issue is avoided and turned into a positive for your operation.

While gas flaring does get rid of excess gas, it is often unfortunately categorized as a waste product. Flare gas contains free energy that can easily be put to work making electricity. The process of getting more value from flare gas is simple and cost effective:

- capture the flare gas

- burn flare gas as fuel

- heat a fluid in a boiler

- convert the heat into electricity

As it is burned, the exhaust can be scrubbed prior to release into the atmosphere to comply with air quality standards. This process has potential for additional value downstream in carbon credit markets. This process applies for oil and gas well sites and refineries. Higher temperature heat sources – such as thermal oils and exhaust gases – can also be harnessed with the deployment of an additional heat exchanger.

All told, rethinking how the value of flare gas in your operation has the benefit of reducing waste, reducing air pollution, generating electricity and potentially increasing revenue.

See our case study on the demonstration of the Power+ unit which eliminates gas flaring and produces electricity from flare gases.

Geothermal co-production for active oil and gas sites

Geothermal is another technology that can easily take advantage of industrial waste heat. It has the essential factors necessary for a good ROI – consistent, predictable flow of excess heat that is already contained within a pipeline system. As stated in The Way Ahead, Society of Petroleum Engineers, the oil and gas industry is turning its focus to growth in the geothermal market.

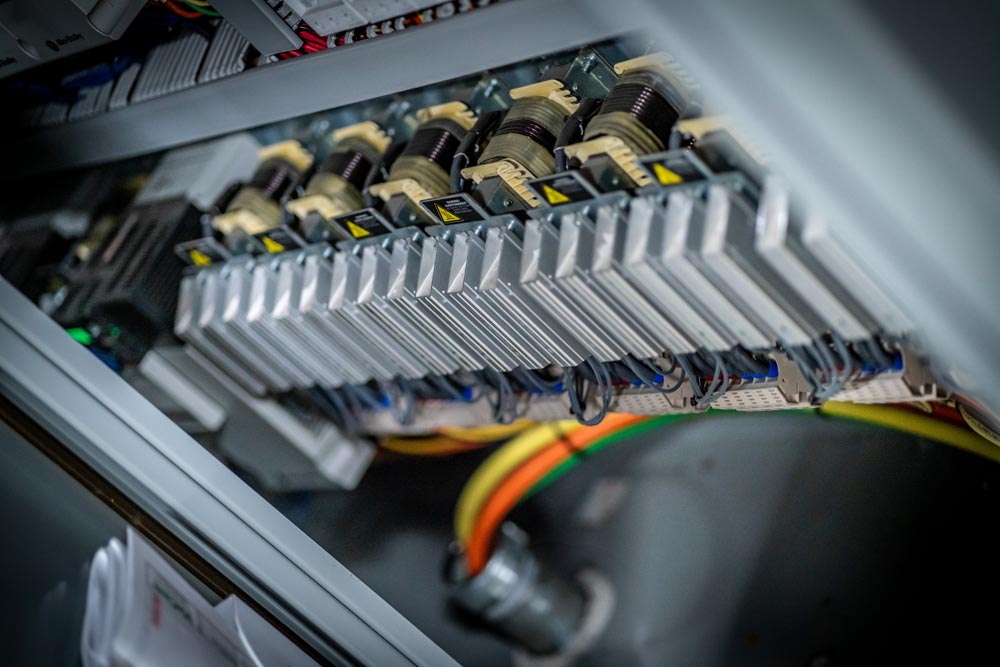

Technologies developed for fracking are starting to be applied directly to generating heat. The temperature of the earth in deep wells is considered a low temperature, or low quality heat. In fact, it is ideally suited to the ORC process and technologies built into ElectaTherm’s units.

The consistent temperature and flow is ideally suited to the ORC process in the Power Module 75. Temperatures from 65 – 132°C (150 – 270°F) yield energy from geothermal production.

The lower temperature of the heat extracted from the ground is in the sweet spot. As with other applications above, this heat recovery cycle generates electricity that can be put to work immediately on-site. ElectraTherm’s heat recovery systems, which are ideal for small- and mid-scale applications, utilize low temperature heat sources previously deemed insufficient for power generation.

Using the organic Rankine cycle (ORC) and proprietary technologies, ElectraTherm equipment converts sources of geothermal heat and waste heat into electricity with no additional emissions or fuel consumption. The return on investment is 2-5 years for most applications.

See our Project Evaluation Form to estimate your savings.

Get in touch with us at sales@electratherm.com

Heat recovery from:

- industrial engine exhaust

- compressor station

- gas compression

- jacketwater

- let down station

- coproduced fluid

- pipeline compression

- pipeline compressors

- heat reuse

Achieve Net-Zero Cooling

Generate Clean Power

By integrating an Active Cooler, ElectraTherm’s premier cooling to power solution, operators can benefit from the generation of electricity in addition to net-zero cooling. Compression stations routinely combust fuel in order to power their process, including the cooling system. Cooling at these sites will always be required, with an Active Cooler now you can benefit from the heat. The ORC process reduces the cooling load 70-100% while generating power, allowing the ElectraTherm system to prioritize the production of electricity asides for times of peak cooling demand. During these times the ORC will be bypassed and the system will provide solely cooling, this is the only time the system will use power not its own.

The offset capital cost by serving as a radiator alternative along with the Consolidated Appropriations Act 2021 offering a 26% tax credit for applicable waste heat recovery projects makes this a sound investment for large scale implementation.

Exceed Air Quality Standards

Reduce or eliminate Gas flaring

One of the benefits of ElectraTherm’s ORC solutions is the ability to capture gas that would otherwise be flared at well sites, biogas plants, and wastewater treatment facilities. Once captured, the thermal energy can be used as fuel for our ORC system to generate clean power. Not only is the power generated emission-free, but by capturing the excess gas you effectively reduce site emissions. With the appropriate system in place, flaring can be substantially reduced or even eliminated – offering numerous environmental benefits.

HESS Demonstration Findings:

Carbon monoxide decreased by 98%

Nitrogen oxide decreased by 48%

VOCs decreased by 93%

Geothermal Power From

Co-Produced Fluids

Well operators have more than oil and gas under their feet, they have water too, hot water. Commonly known as co-produced fluids, this mixture of water is a byproduct of the extraction of oil and gas. Traditionally, this resource has been seen as a nuisance – costing the oil and gas industry billions due to their costly removal and inability to generate power with steam turbines.

With ElectraTherm’s ORC systems this low-temperature geothermal energy can now be converted into electricity. By taking advantage of this existing resource you can extend the economic viability of operations, improve your bottom line, and add renewable energy to your power portfolio.

Increase Efficiency

Maximize Revenue

ElectraTherm offers two means of retrofitting gas compressors. The first is through the integration of an Active Cooler to capture heat from the jacket water to provide net-zero cooling as well as power generation. The second is by integrating a Power+ Generator to capture heat from the exhaust to provide solely power generation. This solution generates more electricity but requires a cooling system and exhaust gas heat exchanger – leading to a slightly increased capital cost.

Our solutions are able to increase efficiency up to 10% – either by generating 10% more power with no additional emissions, or by reducing fuel consumption and emissions by 10%. However you apply efficiency improvements, it improves your bottom line and the environment.

Off-The-Grid Power Supply

For the upstream and midstream sectors, improving energy efficiency has been a challenge due to the high costs associated with infrastructure development. With an ElectraTherm ORC, these sectors can now easily and cost-effectively take steps to reach their sustainability milestones.

In addition to the numerous environmental advantages waste heat recovery offers, ElectraTherm’s ORC systems are also capable of providing a reliable standalone electrical supply in remote areas.

The onsite production of electricity allows operators to benefit from the use of…

// electric radiators

// pneumatic valves

// VRU – vapor recovery units

// electrical heat tracing

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.