Application: Industrial Waste Heat, Compression Heat Recovery

Power Output: 45 kW

Hot Water Inlet Temperature: 85°C

Hot Water Flow Rate: 13 l/s

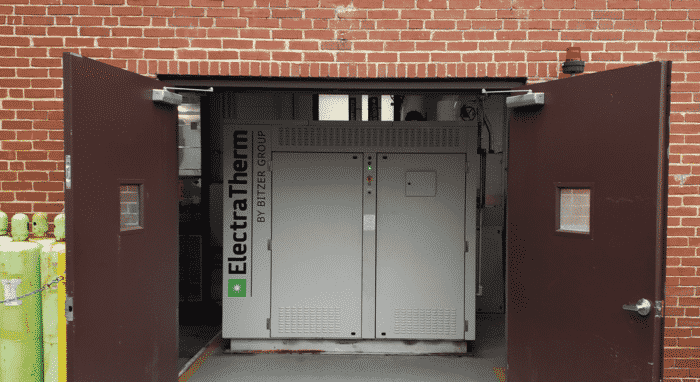

ElectraTherm, an industry-leader in low temperature Organic Rankine Cycle (ORC) systems, installed a Power+ Generator at a pharmaceutical facility in Virginia on a compression heat recovery application to take advantage of the waste heat. The facility makes use of a 500 kW water-cooled air compression system that runs 24/7, generating considerable amounts of heat in the process.

The Power+ Generator is in sync with the air compressor, running continuously without any performance shortcomings. The ORC system generates 45 kW gross, equal to 394 MWh annually. ElectraTherm’s heat recovery solutions also have a cooling effect on the jacket water loop leading to significantly reduced intercooler temperatures, further reducing energy costs/demand and even allowing for the Power+ Generator, or Active Cooler, to serve as a radiator alternative.

Engine or compression applications that are water-cooled provide excellent waste heat recovery opportunities, yielding some of the highest outputs with the lowest capital cost. In addition to lower operating costs, operators can look into installing an Active Cooler, ElectraTherm’s net-zero cooling to power solution.