Biochar Production (Pyrolysis)

& Profit from Carbon Credits

Biochar Production via Pyrolysis or Gasification

Biochar can be created from a range of agricultural feedstocks such as wood, nuts, shells, litters, manures, straw and stalks all can contribute to this process. The result is a usable, marketable product that is growing in demand across the world.

Biochar production through either pyrolysis or gasification are two of the simplest, most measurable and cost-effective methods of carbon capture and storage (CCS) available today. Biochar production generates a massive amount of heat, between 350 to 900° C, which is often lost to the environment if not reused within the process. Capturing and using that heat adds value to your operation when reused or converted to usable electricity. Operating costs can be normalized and predictable. The cost of energy used in operations can be reduced,flattened and predictable over time since the energy is only related to the amount of heat and not dependent upon grid utility prices. Lastly, generating onsite carbon-free electricity may increase the quality and quantity of Carbon Removal Credits ( CDR ) / carbon credits.

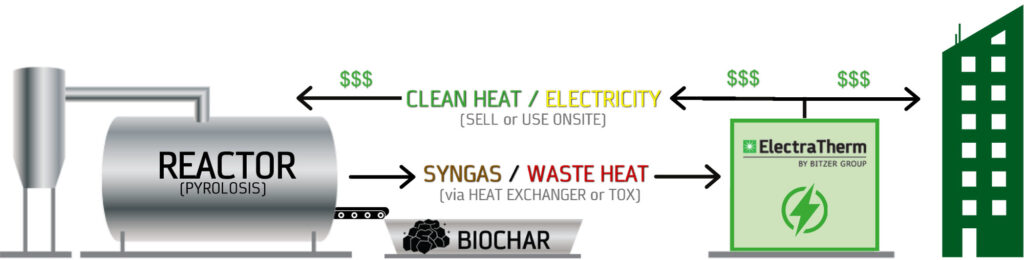

Generating Electricity from the Biochar Process

The heat which is lost to the air can be captured and harnessed to create electricity. That electricity can go right back into your operation to reduce operating costs, or put to use in other ways. By capturing this otherwise vented heat, biochar producers can get more value from their existing biochar process and feedstock. ElectraTherm’s units provide a very simple option to capture and harness biochar heat, and then convert that energy to 75-250 kW of power per unit. Once the electricity is generated, it can be used easily in any application across your enterprise.

Our Power Module75 produces fuel-free, emission-free power from various low-grade waste heat sources using the Organic Rankine Cycle (ORC) and the company’s patented BITZER semi-hermetic twin screw expander/generator combination. Our Power+ Generator, our heat to power solution, is designed to generate clean electricity from sources of low temperature heat. The Power+ Generator also doubles as a combined heat and power (CHP) unit, generating up to 85°C of usable thermal in addition to electricity.

This application of creating electricity from the biochar waste heat is efficient and capitalizes on the basic principle of reducing waste. It is best suited for stationary applications where the biochar processing takes place in a fixed-location facility.

Generating Carbon Credits from the Biochar Process

Organic feedstock sources such as wood, nuts, shells, litters, manures, straw and stalks are high in carbon — in the range of 60-80%. Because they are renewable resources and relatively fast growing, they are good solutions for carbon capture – an increasing business opportunity for both farmers and biochar producers.

Biochar as a product is an industrial-scale, commercial solution that allows carbon sequestration. Because the raw materials (e.g. straw, grasses, nut shells, manures, etc) are well understood and in high-volume production, the value of biochar carbon credits tends to be fairly attractive. This economic cycle is robust enough that it is not difficult to find brokers that specialize in selling carbon credits from biochar.

One benefit of carbon removal via biochar is that it is permanent. Once the carbon is captured by the plant and processed into biochar, it is extremely stable and durable. It has myriad uses in both developed and developing economies.

The criteria for receiving carbon credits from biochar generally include:

- Using sustainable biomass

- Biochar pyrolysis equipment

- Market to sell the biochar

- Registration with a carbon credit governing body, or a certified professional that can manage the process for you

The Market for Biochar Carbon Credits

“Demand for biochar carbon credits has doubled each of the last two years, with prices trading consistently over USD100/metric tonne of carbon dioxide equivalent. The latest modeling by MSCI Carbon Markets suggests demand for this project type could grow 20-fold over the next 10 years.”

—Report from investment advisors MSCI

Biochar is treated in the marketplace as a carbon removal technology, often called carbon capture and storage, or CCS. As the markets for CCS continue to grow due to government mandates, the economics of the market for biochar carbon credits naturally will grow along with it. The use for biochar itself as a product has sufficient benefit to stand on its own. When you add in the fact that carbon credits are available for biochar producers, the business model becomes even more attractive.

Per MSCI, the price for biochar carbon credits has been in the range of $100-200 USD. As with other markets, the price will vary. One helpful aspect of biochar is that it can be produced from a wide range of feedstocks. As a producer, accessing lower cost feedstock is another variable at your disposal to meet your financial and production goals.

The Market for Biochar as a Product

Inherent to every biochar pyrolysis system is the presence of a high temperature operation, often exceeding 700°C, which makes it ideal opportunity for waste heat recovery power generation. This is true whether the feed stock in question is agricultural biomass such as rice hulls, sugar cane fiber (also called bagasse), or tree nut hulls, other biomass such as timber, logging, lumber, or tree service “slash”, or biosolids related to large scale animal lots such as poultry litter, or swine and beef waste lagoons.

According to Fortune Business Insights, the global biochar market was $763 million in 2024, and is projected to grow to $2.1 billion by 2032. Renewable energy mandates target biochar as a scalable market for carbon capture and downstream revenue. Biochar can be used on its own or as ingredients in landscaping products.

Biochar as a product has a wide range of applications already built into the developed and developing economy.

- Soil health: agriculture, garden, landscaping, turf, trees, horticulture, composting

- Environmental: environmental remediation, erosion control, wetlands, odor reduction

- Water: storm water filtration, water treatment, functionalized chars, 3D aerogels

- Forestry: wildfire fuel reduction, reforestation, growing media, revegetation

- Carbon: carbon sequestration, carbon credits, renewable energy offsets

Source: US Biochar Initiative

Adding waste heat recovery power generation

to a pyrolysis application provides multiple benefits

CARBON CREDIT VALUE

Almost all biochar operators today are seeking to capitalize on the financial opportunities related to carbon removal, also known as CDR Credits available through the Voluntary Carbon Market (VCM). Pairing energy production through waste heat recovery represents an opportunity to drive the value of the resultant biochar product through the reduction of the commodity’s carbon intensity.

REGULATORY COMPLIANCE

Waste Heat Power Generation helps reduce carbon emissions taxes and is well-situated to aid in upcoming compliance requirements such as the EU Carbon Removal Framework (ECRF).

HIGH TECH HEAT UTILIZATION

Many of the most respected Carbon Credit Certification organizations recommend or require waste heat utilization in order to qualify as a “high tech” heat operation. Waste heat to power generation using ORC power generation meets this need by simultaneously meeting the operations’ electricity needs while reducing its emissions footprint.

REDUCES OPERATIONAL EXPENSES

By reducing (or nearly eliminating) the need for carbon-based power sources (such as electricity from a municipal grid) during pyrolysis operation and replacing it with emissions free power generation, the overall system operating costs are diminished.

INCREASED BIOCHAR VALUE

Biochar which is manufactured in the most carbon friendly manner will be more attractive in an open market as high value “off-takers” seek to source biochar from the certifiably most environmentally friendly suppliers. As such biochar from pyrolysis systems incorporating waste heat power generation will be in higher demand.

Partner Organizations and Resources

Questions?

Contact us for a conversation about your unique project needs.

Use our project evaluation form to jump start the estimating process.