Application: Flare Elimination

Emission Reductions:

Carbon Monoxide by 98%

Nitrogen Oxide by 48%

VOCs by 93%

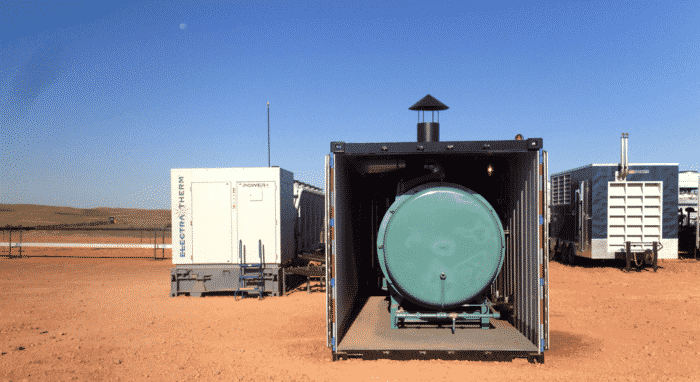

ElectraTherm, an industry-leader in low temperature heat recovery using Organic Rankine Cycle (ORC) systems, commissioned a Power+ Generator at a well site in the Bakken oil field. Funding for this project was provided by the Department of Energy’s Research Partnership to Secure Energy for America (REPSEA) program and was completed in collaboration with HESS, 墨西哥灣綠色能源, the 休士頓先進研究中心 (HARC) Environmentally Friendly Drilling Program.

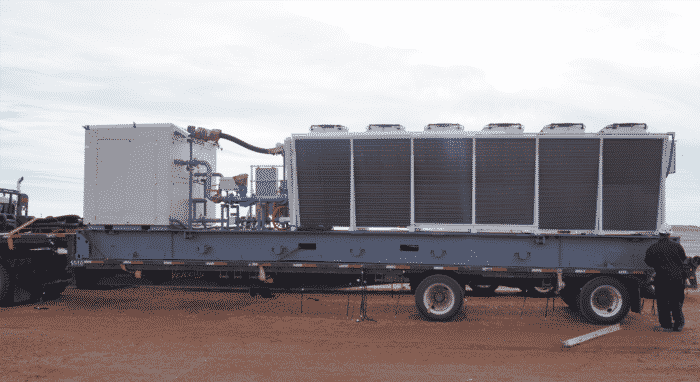

The process for ORC flare elimination is simple, straightforward, and cost-effective. Excess gas is used as fuel for a boiler which heats water for the ORC. This cycle converts the excess gas that would otherwise be flared into emission-free electricity which can be used onsite or sold for profit.. This project successfully demonstrates an effective means of flare reduction and changes the landscape for industries where routine flaring is common, such as at biogas and wastewater treatment plants. The Texas A&M Institute of Renewable Natural Resources (IRNR) conducted research and collected data from the HESS site for a research study comparing emissions with and without the Power+ Generator in place.

Hess Corporation’s 2015 Report includes ElectraTherm’s flare elimination demo as a case study. See it here.

In North Dakota and across the United States, both state regulators and the U.S. Environmental Protection Agency are beginning to require the amount of natural gas burned in flares be substantially reduced or face steep penalties and potential curtailment of oil production at offending wells. ElectraTherm’s ORC system captures the excess heat and provides clean methane utilization without capital intensive gas clean-up, engine or micro turbine capital costs, and the heavy maintenance associated with large infrastructure.

“We’re capturing a wasted fuel source that was being flared to the atmosphere, and putting that fuel to use in the oil fields. The emissions profile of the site is greatly improved, the power is consumed on site and the equipment is easy to install and maintain. Beyond oil and gas, ElectraTherm sees potential for other applications where flaring is a major concern, such as at landfills and waste water treatment plants.”

– John Fox, Chief Executive Officer of ElectraTherm

若要瞭解 ElectraTherm 和最新的廢熱新聞,請訂閱我們的電子報 這裡.

關於 ElectraTherm

BITZER Group 的 ElectraTherm 利用有機朗肯循環及專有技術將低溫熱能轉換為清潔電力,提供世界級的廢熱回收解決方案。ElectraTherm 簡單有效的解決方案可產生乾淨電力、提高效率、降低能源成本並減少廢氣排放,且無需額外消耗燃料。ElectraTherm 已向 13 個國家運送了 100 多台 ORC 裝置,運行時間超過 2,000,000 小時,是小型廢熱回收領域的全球領導者。

BITZER是全球最大的獨立製冷壓縮機製造商,擁有近3,500名全球員工,年均銷售額接近10億美元,ElectraTherm的工程技術優勢與BITZER的支持價值相結合,使ElectraTherm團隊能夠繼續開發行業領先的ORC技術,這對企業和地球都有好處。

ElectraTherm 的 電源+發電機 是一種熱轉電解決方案,可將廢熱轉換為清潔的電力和可用的熱能。該 主動冷卻器 可作為淨零冷卻發電解決方案,使用相同的 ORC 製程在發電的同時提供自供電冷卻。ElectraTherm 的這兩種解決方案均可減少排放和能源成本,同時提供基荷電力/冷卻供給。利用廢熱不僅有利可圖,而且非常實用。讓企業在實現可持續發展目標的同時,從更多的循環經濟中獲益。