Application: Flare Elimination

Emission Reductions:

Carbon Monoxide by 98%

Nitrogen Oxide by 48%

VOCs by 93%

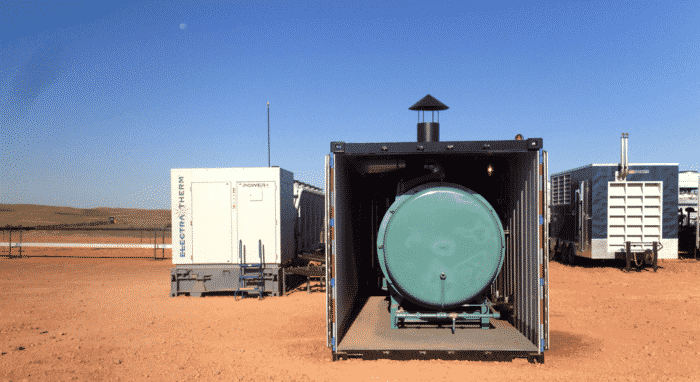

ElectraTherm, an industry-leader in low temperature heat recovery using Organic Rankine Cycle (ORC) systems, commissioned a Power+ Generator at a well site in the Bakken oil field. Funding for this project was provided by the Department of Energy’s Research Partnership to Secure Energy for America (REPSEA) program and was completed in collaboration with HESS, Gulf Coast Green Energy, the Houston Advanced Research Center (HARC) Environmentally Friendly Drilling Program.

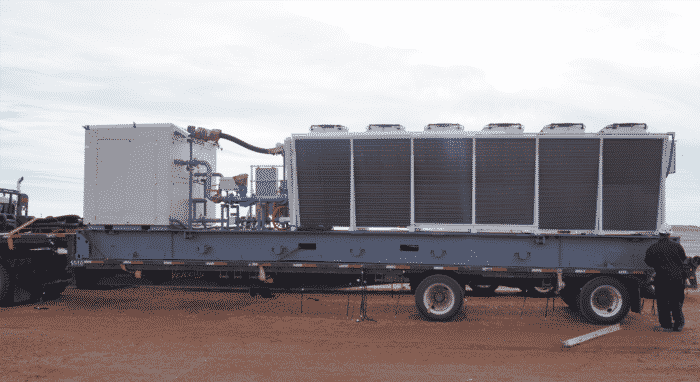

The process for ORC flare elimination is simple, straightforward, and cost-effective. Excess gas is used as fuel for a boiler which heats water for the ORC. This cycle converts the excess gas that would otherwise be flared into emission-free electricity which can be used onsite or sold for profit.. This project successfully demonstrates an effective means of flare reduction and changes the landscape for industries where routine flaring is common, such as at biogas and wastewater treatment plants. The Texas A&M Institute of Renewable Natural Resources (IRNR) conducted research and collected data from the HESS site for a research study comparing emissions with and without the Power+ Generator in place.

Hess Corporation’s 2015 Report includes ElectraTherm’s flare elimination demo as a case study. See it here.

In North Dakota and across the United States, both state regulators and the U.S. Environmental Protection Agency are beginning to require the amount of natural gas burned in flares be substantially reduced or face steep penalties and potential curtailment of oil production at offending wells. ElectraTherm’s ORC system captures the excess heat and provides clean methane utilization without capital intensive gas clean-up, engine or micro turbine capital costs, and the heavy maintenance associated with large infrastructure.

“We’re capturing a wasted fuel source that was being flared to the atmosphere, and putting that fuel to use in the oil fields. The emissions profile of the site is greatly improved, the power is consumed on site and the equipment is easy to install and maintain. Beyond oil and gas, ElectraTherm sees potential for other applications where flaring is a major concern, such as at landfills and waste water treatment plants.”

– John Fox, Chief Executive Officer of ElectraTherm

Para estar al día sobre ElectraTherm y las últimas noticias sobre calor residual, suscríbase a nuestro boletín de noticias aquí.

Acerca de ElectraTherm

ElectraTherm by BITZER Group proporciona soluciones de recuperación de calor residual de primera clase utilizando el Ciclo Rankine Orgánico junto con tecnologías propias para convertir el calor de baja temperatura en energía limpia. Las soluciones sencillas y eficaces de ElectraTherm generan electricidad limpia, aumentan la eficiencia, reducen los costes energéticos y disminuyen las emisiones, sin consumo adicional de combustible. Con más de 100 unidades ORC suministradas a más de 13 países y más de 2.000.000 de horas de funcionamiento, ElectraTherm es líder mundial en recuperación de calor residual a pequeña escala.

La ventaja combinada de la ingeniería de ElectraTherm junto con el valor de contar con el apoyo de BITZER, el mayor fabricante independiente de compresores de refrigeración del mundo que cuenta con cerca de 3.500 empleados en todo el mundo y unas ventas medias anuales que se aproximan a los $1.000 millones, permite al equipo de ElectraTherm continuar desarrollando una tecnología ORC líder en la industria que es buena tanto para los negocios como para el planeta.

ElectraTherm Generador Power es una solución de conversión del calor residual en electricidad limpia y energía térmica utilizable. El sitio Enfriador activo sirve como solución de refrigeración neta cero a energía, utilizando el mismo proceso ORC para proporcionar refrigeración autoalimentada a la vez que genera electricidad. Ambas soluciones de ElectraTherm reducen las emisiones y los costes energéticos a la vez que proporcionan un suministro básico de electricidad/refrigeración. Aprovechar el calor residual no sólo es rentable, sino práctico. Permite a las empresas beneficiarse de una economía más circular al tiempo que alcanzan objetivos de sostenibilidad.